return to Practical Engineering

We've split our info on insulation into two separate pages: Insulation Data and Insulation Products. You are currently on the Insulation Data page. Here you will find charts on R values and temp tolerance for common insulative materials. The Insulation Products page is our running reference and commentary on where, what and why of various products we have tried and might have something to say about them.

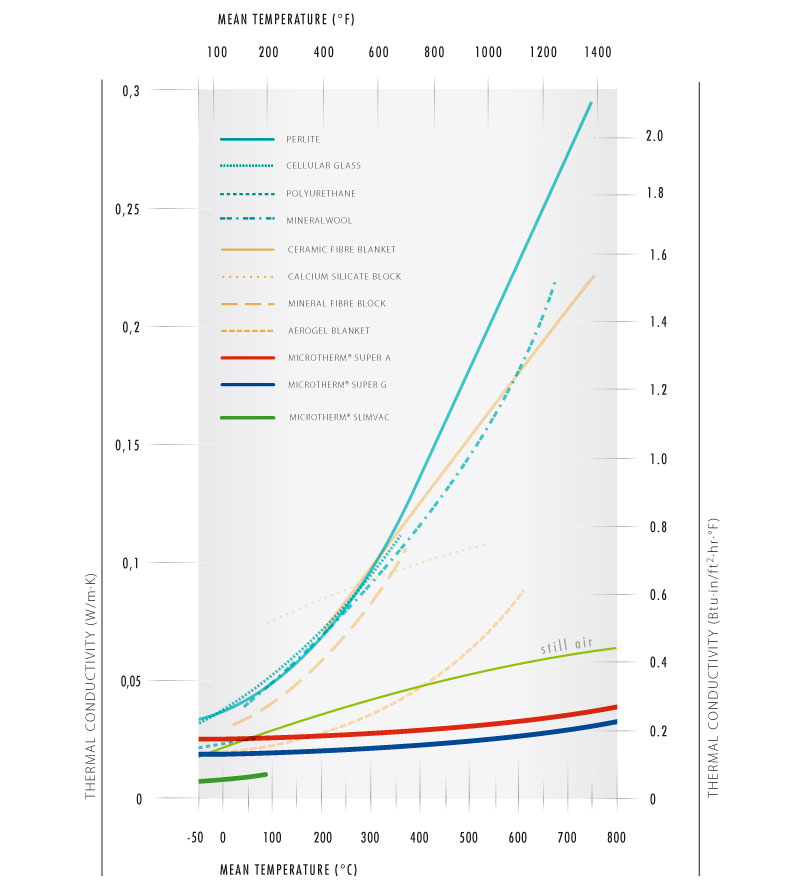

Insulation for gasifiers needs to be concerned with both insulative performance and tolerance to high temperature. In general, as high temperature tolerance increases, insulative performance decreases. Most of the refractory ceramics that are survive high temps very well, also tend to be relatively poor insulators. Of course money and esoteric materials can find exceptions to this trend, but such is the starting point from which to get oriented. One can also consider layering insulation materials, so that temp resistance is favored against the heat source, and insulative performance is favored for surrounding layers.

Here now is a helpful summary chart from wikipedia for understanding relative insulation performance. Note that some relatively common materials and inexpensive materials are good insulators. Exotic high cost insulators are not necessarily an improvement. The chart shows numerically why we have found Perlite to be a great insulative value.

This chart rates insulators with their R value. A higher R value is better insulation. Formally, R value = material thickness / thermal conductivity. Thus R value is the inverse of thermal conductivity. There is a very complete thermal conductivity chart on the bottom of this page.

| Material | Value per inch (Min) | Value per inch (Max) | Reference |

|---|

| Still Air |

|

R-5 (0.88) |

|

|---|

| Still Air with convective currents |

R-1 (0.18) (or less) |

R-5 (0.88) (Still) |

|

|---|

| Wood chips and other loose-fill wood products |

R-1 (0.18) |

|

|

|---|

| Snow |

R-1 (0.18) |

|

|

|---|

| Straw bale |

R-1.45 (0.26) |

|

[3] |

|---|

| Wood panels, such as sheathing |

R-2.5 (0.44) |

|

|

|---|

| Vermiculite loose-fill |

R-2.13 (0.38) |

R-2.4 (0.42) |

|

|---|

| Perlite loose-fill |

R-2.7 (0.48) |

|

|

|---|

| Rock and slag wool loose-fill |

R-2.5 (0.44) |

R-3.7 (0.65) |

[8] |

|---|

| Rock and slag wool batts |

R-3 (0.52) |

R-3.85 (0.68) |

|

|---|

| Fiberglass loose-fill |

R-2.5 (0.44) |

R-3.7 (0.65) |

[8] |

|---|

| Fiberglass rigid panel |

R-2.5 (0.44) |

|

|

|---|

| Fiberglass batts |

R-3.1 (0.55) |

R-4.3 (0.76) |

|

|---|

| High-density fiberglass batts |

R-3.6 (0.63) |

R-5 (0.88) |

|

|---|

| Cementitious foam |

R-2 (0.35) |

R-3.9 (0.69) |

|

|---|

| Cellulose loose-fill |

R-3 (0.52) |

R-3.8 (0.67) |

[9] |

|---|

| Cellulose wet-spray |

R-3 (0.52) |

R-3.8 (0.67) |

[9] |

|---|

| Cotton batts (Blue Jean Insulation) |

R-3.7 (0.65) |

|

[10] |

|---|

| Icynene spray |

R-3.6 (0.63) |

|

[11] |

|---|

| Icynene loose-fill (pour fill) |

R-4 (0.70) |

|

[11] |

|---|

| Urea-formaldehyde foam |

R-4 (0.70) |

R-4.6 (0.81) |

|

|---|

| Urea-formaldehyde panels |

R-5 (0.88) |

R-6 (1.06) |

|

|---|

| Polyethylene foam |

R-3 (0.52) |

|

|

|---|

| Phenolic spray foam |

R-4.8 (0.85) |

R-7 (1.23) |

|

|---|

| Phenolic rigid panel |

R-4 (0.70) |

R-5 (0.88) |

|

|---|

| Molded expanded polystyrene (EPS) low-density |

R-3.7 (0.65) |

|

|

|---|

| Molded expanded polystyrene (EPS) high-density |

R-4 (0.70) |

|

|

|---|

| Extruded expanded polystyrene (XPS) low-density |

R-3.6 (0.63) |

R-4.7 (0.82) |

|

|---|

| Extruded expanded polystyrene (XPS) high-density |

R-5 (0.88) |

R-5.4 (0.95) |

|

|---|

| Open-cell polyurethane spray foam |

R-3.6 (0.63) |

|

|

|---|

| Closed-cell polyurethane spray foam |

R-5.5 (0.97) |

R-6.5 (1.14) |

|

|---|

| Polyurethane rigid panel (Pentane expanded) initial |

R-6.8 (1.20) |

|

|

|---|

| Polyurethane rigid panel (Pentane expanded) aged 5-10 years |

R-5.5 (0.97) |

|

|

|---|

| Polyurethane rigid panel (CFC/HCFC expanded) initial |

R-7 (1.23) |

R-8 (1.41) |

|

|---|

| Polyurethane rigid panel (CFC/HCFC expanded) aged 5-10 years |

R-6.25 (1.10) |

|

|

|---|

| Polyisocyanurate spray foam |

R-4.3 (0.76) |

R-8.3 (1.46) |

|

|---|

| Foil-faced polyisocyanurate rigid panel (Pentane expanded ) initial |

R-6.8 (1.20) |

|

|

|---|

| Foil-faced polyisocyanurate rigid panel (Pentane expanded) aged 5-10 years |

R-5.5 (0.97) |

|

|

|---|

| Silica aerogel |

R-10 (1.76) |

|

|

|---|

| Vacuum insulated panel |

R-30 (5.28) |

R-50 (8.80) |

|

|---|

| Cardboard |

R-3 (0.52) |

R-4 (0.70) |

|

|---|

| Thinsulate clothing insulation |

R-5.75 (1.01) |

|

|

|---|

chart from Wikipedia: http://en.wikipedia.org/wiki/R-value_(insulation)

Detailed info on Perlite insulation over temp range

http://www.engineeringtoolbox.com/perlite-insulation-k-values-d_1173.html

Detailed info on Mineral Wool insulation over temp range

http://www.engineeringtoolbox.com/mineral-wool-insulation-k-values-d_815.html

Detailed Info on Fiberglass insulation over temp range

http://www.engineeringtoolbox.com/fiberglas-insulation-k-values-d_1172.html

Detailed Info on Polyurethane insulation over temp range

http://www.engineeringtoolbox.com/polyurethane-insulation-k-values-d_1174.html

Other R value charts

http://www.coloradoenergy.org/procorner/stuff/r-values.htm

http://www.progress-energy.com/custservice/flares/billtoolkit/rvalues.asp

Temperature limits of some common insulation materials are indicated in the table below:

| Insulation Material |

Low Temperature Range |

High Temperature Range |

| (oC) |

(oF) |

(oC) |

(oF) |

| Calcium Silicate |

-18 |

0 |

650 |

1200 |

| Cellular Glass |

-260 |

-450 |

480 |

900 |

| Elastomeric foam |

-55 |

-70 |

120 |

250 |

| Fiberglass |

-30 |

-20 |

540 |

1000 |

| Mineral Wool |

0 |

32 |

1000 |

1800 |

| Phenolic foam |

|

|

150 |

300 |

| Polyisocyanurate or polyiso |

-180 |

-290 |

150 |

300 |

| Polystyrene |

-50 |

-60 |

75 |

165 |

| Polyurethane |

-210 |

-350 |

120 |

250 |

from Engineering Toolbox: http://www.engineeringtoolbox.com/insulation-temperatures-d_922.html

Charts of Thermal Conductivity

Thermal conductivity, or heat transfer coefficients, of some common materials and products are indicated in the table below.

|

Thermal Conductivity - k - (W/mK)

|

|

Material/Substance

|

Temperature (oC)

|

|

25

|

125

|

225

|

|

Acetone

|

0.16

|

|

|

|

Acrylic

|

0.2

|

|

|

|

Air

|

0.024

|

|

|

|

Alcohol

|

0.17

|

|

|

|

Aluminum

|

250

|

255

|

250

|

|

Aluminum Oxide

|

30

|

|

|

|

Ammonia

|

0.022

|

|

|

|

Antimony

|

18.5

|

|

|

|

Argon

|

0.016

|

|

|

|

Asbestos-cement board

|

0.744

|

|

|

|

Asbestos-cement sheets

|

0.166

|

|

|

|

Asbestos-cement

|

2.07

|

|

|

|

Asbestos, loosely packed

|

0.15

|

|

|

|

Asbestos mill board

|

0.14

|

|

|

|

Asphalt

|

0.75

|

|

|

|

Balsa

|

0.048

|

|

|

|

Bitumen

|

0.17

|

|

|

|

Benzene

|

0.16

|

|

|

|

Beryllium

|

218

|

|

|

|

Brass

|

109

|

|

|

|

Brick dense

|

1.31

|

|

|

|

Brick work

|

0.69

|

|

|

|

Cadmium

|

92

|

|

|

|

Carbon

|

1.7

|

|

|

|

Carbon dioxide

|

0.0146

|

|

|

|

Cement, portland

|

0.29

|

|

|

|

Cement, mortar

|

1.73

|

|

|

|

Chalk

|

0.09

|

|

|

|

Chrome Nickel Steel (18% Cr, 8 % Ni)

|

16.3

|

|

|

|

Clay, dry to moist

|

0.15 - 1.8

|

|

|

|

Clay, saturated

|

0.6 - 2.5

|

|

|

|

Cobalt

|

69

|

|

|

|

Concrete, light

|

0.42

|

|

|

|

Concrete, stone

|

1.7

|

|

|

|

Constantan

|

22

|

|

|

|

Copper

|

401

|

400

|

398

|

|

Corian (ceramic filled)

|

1.06

|

|

|

|

Corkboard

|

0.043

|

|

|

|

Cork, regranulated

|

0.044

|

|

|

|

Cork

|

0.07

|

|

|

|

Cotton

|

0.03

|

|

|

|

Carbon Steel

|

54

|

51

|

47

|

|

Cotton Wool insulation

|

0.029

|

|

|

|

Diatomaceous earth (Sil-o-cel)

|

0.06

|

|

|

|

Earth, dry

|

1.5

|

|

|

|

Ether

|

0.14

|

|

|

|

Epoxy

|

0.35

|

|

|

|

Felt insulation

|

0.04

|

|

|

|

Fiberglass

|

0.04

|

|

|

|

Fiber insulating board

|

0.048

|

|

|

|

Fiber hardboard

|

0.2

|

|

|

|

Fireclay brick 500oC

|

1.4

|

|

|

|

Foam glass

|

0.045

|

|

|

|

Freon 12

|

0.073

|

|

|

|

Gasoline

|

0.15

|

|

|

|

Glass

|

1.05

|

|

|

|

Glass, Pearls, dry

|

0.18

|

|

|

|

Glass, Pearls, saturated

|

0.76

|

|

|

|

Glass, window

|

0.96

|

|

|

|

Glass, wool Insulation

|

0.04

|

|

|

|

Glycerol

|

0.28

|

|

|

|

Gold

|

310

|

312

|

310

|

|

Granite

|

1.7 - 4.0

|

|

|

|

Gypsum or plaster board

|

0.17

|

|

|

|

Hairfelt

|

0.05

|

|

|

|

Hardboard high density

|

0.15

|

|

|

|

Hardwoods (oak, maple..)

|

0.16

|

|

|

|

Helium

|

0.142

|

|

|

|

Hydrogen

|

0.168

|

|

|

|

Ice (0oC, 32oF)

|

2.18

|

|

|

|

Insulation materials

|

0.035 - 0.16

|

|

|

|

Iridium

|

147

|

|

|

|

Iron

|

80

|

68

|

60

|

|

Iron, wrought

|

59

|

|

|

|

Iron, cast

|

55

|

|

|

|

Kapok insulation

|

0.034

|

|

|

|

Kerosene

|

0.15

|

|

|

|

Lead Pb

|

35

|

|

|

|

Leather, dry

|

0.14

|

|

|

|

Limestone

|

1.26 - 1.33

|

|

|

|

Magnesia insulation (85%)

|

0.07

|

|

|

|

Magnesite

|

4.15

|

|

|

|

Magnesium

|

156

|

|

|

|

Marble

|

2.08 - 2.94

|

|

|

|

Mercury

|

8

|

|

|

|

Methane

|

0.030

|

|

|

|

Methanol

|

0.21

|

|

|

|

Mica

|

0.71

|

|

|

|

Mineral insulation materials, wool blankets ..

|

0.04

|

|

|

|

Molybdenum

|

138

|

|

|

|

Monel

|

26

|

|

|

|

Nickel

|

91

|

|

|

|

Nitrogen

|

0.024

|

|

|

|

Nylon 6

|

0.25

|

|

|

|

Oil, machine lubricating SAE 50

|

0.15

|

|

|

|

Olive oil

|

0.17

|

|

|

|

Oxygen

|

0.024

|

|

|

|

Paper

|

0.05

|

|

|

|

Paraffin Wax

|

0.25

|

|

|

|

Perlite, atmospheric pressure

|

0.031

|

|

|

|

Perlite, vacuum

|

0.00137

|

|

|

|

Plaster, gypsum

|

0.48

|

|

|

|

Plaster, metal lath

|

0.47

|

|

|

|

Plaster, wood lath

|

0.28

|

|

|

|

Plastics, foamed (insulation materials)

|

0.03

|

|

|

|

Plastics, solid

|

|

|

|

|

Platinum

|

70

|

71

|

72

|

|

Plywood

|

0.13

|

|

|

|

Polyethylene HD

|

0.42 - 0.51

|

|

|

|

Polypropylene

|

0.1 - 0.22

|

|

|

|

Polystyrene expanded

|

0.03

|

|

|

|

Porcelain

|

1.5

|

|

|

|

PTFE

|

0.25

|

|

|

|

PVC

|

0.19

|

|

|

|

Pyrex glass

|

1.005

|

|

|

|

Quartz mineral

|

3

|

|

|

|

Rock, solid

|

2 - 7

|

|

|

|

Rock, porous volcanic (Tuff)

|

0.5 - 2.5

|

|

|

|

Rock Wool insulation

|

0.045

|

|

|

|

Sand, dry

|

0.15 - 0.25

|

|

|

|

Sand, moist

|

0.25 - 2

|

|

|

|

Sand, saturated

|

2 - 4

|

|

|

|

Sandstone

|

1.7

|

|

|

|

Sawdust

|

0.08

|

|

|

|

Silica aerogel

|

0.02

|

|

|

|

Silicone oil

|

0.1

|

|

|

|

Silver

|

429

|

|

|

|

Snow (temp < 0oC)

|

0.05 - 0.25

|

|

|

|

Sodium

|

84

|

|

|

|

Softwoods (fir, pine ..)

|

0.12

|

|

|

|

Soil, with organic matter

|

0.15 - 2

|

|

|

|

Soil, saturated

|

0.6 - 4

|

|

|

|

Steel, Carbon 1%

|

43

|

|

|

|

Stainless Steel

|

16

|

17

|

19

|

|

Straw insulation

|

0.09

|

|

|

|

Styrofoam

|

0.033

|

|

|

|

Tin Sn

|

67

|

|

|

|

Zinc Zn

|

116

|

|

|

|

Urethane foam

|

0.021

|

|

|

|

Vermiculite

|

0.058

|

|

|

|

Vinyl ester

|

0.25

|

|

|

|

Water

|

0.58

|

|

|

|

Water, vapor (steam)

|

|

0.016

|

|

|

Wood across the grain, white pine

|

0.12

|

|

|

|

Wood across the grain, balsa

|

0.055

|

|

|

|

Wood across the grain, yellow pine

|

0.147

|

|

|

|

Wood, oak

|

0.17

|

|

|

|

Wool, felt

|

0.07

|

|

|

from Engineering Toolbox: http://www.engineeringtoolbox.com/thermal-conductivity-d_429.html

Properties of some common ceramics are indicated in the table below:

| Material |

Specific Gravity |

Coefficient of Linear Expansion

(106ppm/oC) |

Maximum Safe Operating Temperature

(oC) |

Thermal Conductivity

(10-3cal/cm2/ cm/sec/oC) |

Tensile Strength

(psi) |

Compressive Strength

(psi) |

Flexural Strength

(psi) |

Modulus of Elasticity

(106 psi) |

| Porcelain |

2.2-2.4 |

5.0-6.5 |

400 |

4-5 |

1500-2500 |

25000-50000 |

3500-6000 |

7-10 |

| Alumina Porcelain |

3.1-3.9 |

5.5-8.1 |

1350-1500 |

7-50 |

8000-30000 |

8000-25000 |

20000-45000 |

15-52 |

| High-Voltage Porcelain |

2.3-25.5 |

5.0-6.8 |

1000 |

2-5 |

3000-8000 |

25000-50000 |

9000-15000 |

7-14 |

| Zirconia Porcelain |

3.5-3.8 |

3.5-5.5 |

1000-1200 |

10-15 |

10000-15000 |

80000-150000 |

20000-35000 |

20-30 |

| Lithia Porcelain |

2.3-4 |

1 |

1000 |

|

|

60000 |

8000 |

|

| Cordierite Refractory |

1.6-2.1 |

2.5-3.0 |

1250 |

3-4 |

1000-3500 |

20000-45000 |

1500-7000 |

2-5 |

| Alumina Silicate Refractory |

2.2-2.4 |

5.0-7.0 |

1300-1700 |

4-5 |

700-3000 |

13000-60000 |

1500-6000 |

2-5 |

| Magnesium Silicate |

2.3-2.8 |

11.5 |

1200 |

3-5 |

2500 |

20000-30000 |

7000-9000 |

4-5 |

| Steatite |

2.5-2.7 |

8.6-10.5 |

1000-1100 |

5-6 |

8000-10000 |

65000-130000 |

16000-24000 |

13-15 |

| Forsterite |

2.7-2.9 |

11 |

1000-1100 |

5-10 |

8000-10000 |

60000-100000 |

18000-20000 |

13-15 |

| Titania/Titanate Ceramics |

3.5-5.5 |

7-10 |

|

8-10 |

4000-10000 |

40000-120000 |

10000-22000 |

0.3-0.5 |

- 1 psi (lb/in2) = 6,894.8 Pa (N/m2)

- Porcelain is a ceramic material made by heating selected and refined materials often including clay in the form of kaolinite to high temperatures.

- Cordierite is a crystalline magnesium aluminosilicate

- Steatite, also known as soapstone or soaprock, is a metamorphic rock, a talc-schist. It is largely composed of the mineral talc and is rich in magnesium.

- Forsterite (Mg2SiO4) is the magnesium rich end-member of the olivine solid-solution series.

copied from http://www.engineeringtoolbox.com/ceramics-properties-d_1227.html

Thermal Conductivity at Room Temperature

copied from http://global.kyocera.com/fcworld/charact/heat/thermalcond.html

-----------------------------------------------------------------------------------------

Chart of thermal conductivity changes over temp for common ceramics

ThermalConducityCeramicsOverTemp.pdf

from http://www.engin.brown.edu/organizations/EWB/GISP/Callster%20-%20chapter_17.pdf

----------------------------------------------------------

Microtherm vs Aerogel vs other common ceramic insulators over temp range

--------------------------------------------------------------------------------

Rath ceramic fiber papers http://www.rath-usa.com/pds-ceramic-fiber-paper.html

Convert between different units of Thermal Conductivity (k)

1 W/(mK) = 1 W/(moC) = 0.85984 kcal/(hr moC) = 0.5779 Btu/(ft hr oF)

or use the converter here: http://www.engineeringtoolbox.com/thermal-conductivity-calculator-d_857.html

| Multiply with |

| Convert from |

Convert to |

| Btu ft / (h ft2 oF) |

Btu in / (h ft2 oF) |

Btu in / sec ft2 oF) |

Cal / (cm s oC) |

Kcal / (cm s oC) |

| Btu ft / (h ft2 oF) |

1 |

12 |

0.0033 |

0.0041 |

4.134 10-6 |

| Btu in / (h ft2 oF) |

0.0833 |

1 |

0.000278 |

0.00035 |

3.45 10-7 |

| Btu in / (sec ft2 oF) |

300 |

3600 |

1 |

1.24 |

0.0012 |

| Cal / (cm s oC) |

241.9 |

2903 |

0.806 |

1 |

0.001 |

| Kcal / (cm s oC) |

2.42 105 |

2.9 106 |

806.3 |

1000 |

1 |

| Kcal / (m h oC) |

0.672 |

8.06 |

0.0022 |

0.00278 |

2.778 10-6 |

| Erg / (cm s oC) |

5.78 106 |

6.93 10-5 |

1.92 10-8 |

2.39 10-8 |

2.389 10-11 |

| Joules / (m h oC) |

1.61 10-4 |

0.00193 |

5.35 10-7 |

6.64 10-7 |

6.635 10-10 |

| Watt / (ft oC) |

1.89 |

22.8 |

0.0078 |

0.0078 |

7.84 10-6 |

| Watt / (m oK) |

0.58 |

6.94 |

0.0024 |

0.0024 |

2.39 10-6 |

| Multiply with |

| Convert from |

Convert to |

| Kcal / (m h oC) |

Erg / (cm s oC) |

Joules / (m h oC) |

Watt / (ft oC) |

Watt / (m oK) |

| Btu ft / (h ft2 oF) |

1.49 |

173076 |

6230 |

0.527 |

1.73 |

| Btu in / (h ft2 oF) |

0.124 |

14423 |

519 |

0.044 |

0.14 |

| Btu in / (sec ft2 oF) |

446.5 |

5.19 107 |

1.87 106 |

158.2 |

519 |

| Cal / (cm s oC) |

360 |

4.19 107 |

1.51 106 |

127.6 |

418 |

| Kcal / (cm s oC) |

360000 |

4.19 1010 |

1.51 109 |

1.276 105 |

4.18 105 |

| Kcal / (m h oC) |

1 |

116300 |

4187 |

0.354 |

1.16 |

| Erg / (cm s oC) |

8.6 10-6 |

1 |

0.036 |

3.05 10-6 |

1 10-5 |

| Joules / (m h oC) |

0.00024 |

27.78 |

1 |

8.47 10-5 |

2.78 10-4 |

| Watt / (ft oC) |

2.82 |

328123 |

11811 |

1 |

3.28 |

| Watt / (m oK) |

0.86 |

1 105 |

3600 |

0.305 |

1 |

Here are some more charts of Thermal Conductivity

http://en.wikipedia.org/wiki/Thermal_conductivity

http://en.wikipedia.org/wiki/List_of_thermal_conductivities

Comments (0)

You don't have permission to comment on this page.